For our company, the study of highly composite materials is of particular value. The correctness of the calculations guarantees the combination of optimal performance and economic operation. The design of the system is differentiated based on the product, the requirements and the needs of the customer.

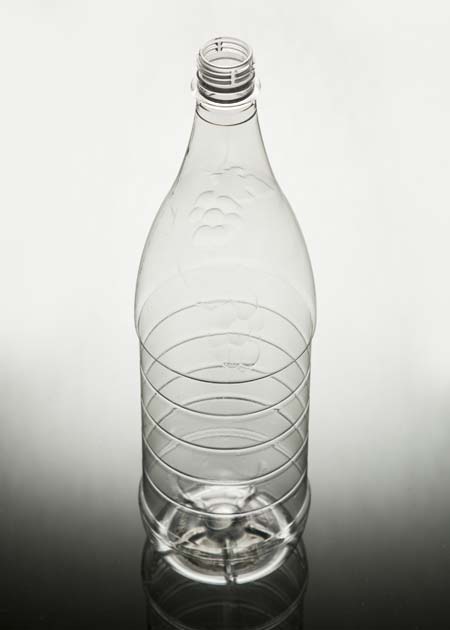

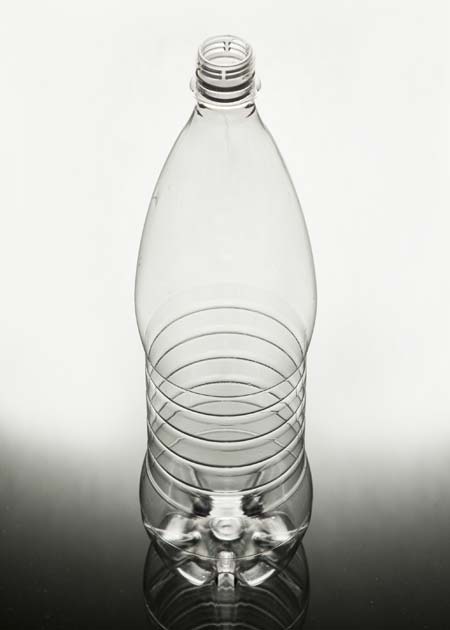

Pet bottle Molds

PACKAGES AND LOGISTIC

As the practice of several companies has shown in the past, product design contributes greatly to improving competitiveness because it allows reducing costs, increasing quality, and often, reducing the time required to bring the product to market.

Based on all these, the product meets, in general, the needs and requirements of the customers. Until a few years ago, the product design and development process essentially focused on determining the characteristics that a product must have in order to be the right answer to specific functional specifications determined by the constraints imposed by the production processes.

However, the design process is now considered from a broader perspective: instead of simply referring to the product features themselves, “external” factors such as:

• Customer requirements

1• The quality

• The reduction of production costs and controls

• The assembly and distribution process

During our many years of presence in the plastic industry, we have established quality as our personal hallmark. The quality of our products is highlighted both by the sophisticated aesthetics and by the reliability and safety of the services provided.

As the high and stable quality of our plastics is a key element of our philosophy, quality control is a key part of our production process. We have modern Quality Control methods for the best possible result in the produced product.